Hall Wheels and Components can offer various heat treatment options to suit your application

Wheel & Sheave Heat Treatment Selections

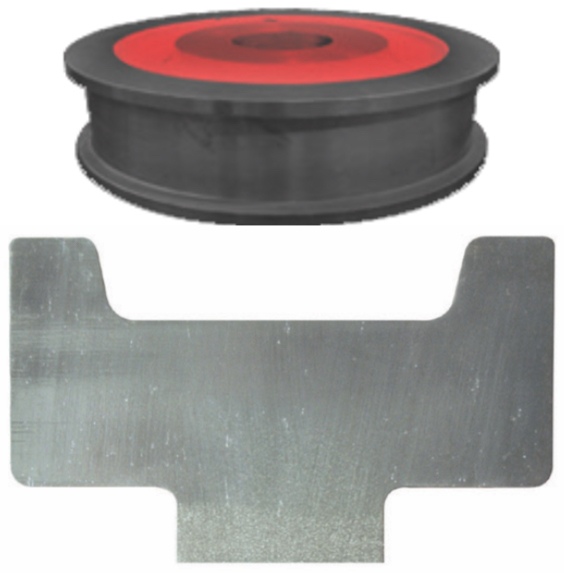

Rim Toughened AISI-1070 Steel

- Rim Toughening is the most popular form of heat treating for Crane Wheels, Industrial Wheels, and Sheaves

- The process involves the uniform heating of the entire wheel rim and then aggressive quenching in a polymer solution while the wheel is spinning

- The most common hardness range for the wheels heat treated in this manner is 321-363 BHN, but other hardness ranges can be achieved as well

- The depth of hardness achieved with this process can reach more than one inch at 321 BHN or above making it the deepest penetrating of the common wheel heat treating practices

- The depth of hardness achieved greatly exceeds the requirements of the AIST Technical Report #6, “Allowable Wheel Loads Guide for Heat Treated (321 BHN Minimum) Crane Wheels”

- The depth of hardness and level of hardness achieved using this process create an extremely tough and durable wheel for moderately loaded wheel applications

- This is the material and hardness range that is specified in ASTM A-504 Class C

Recommended Usages

- Cranes with moderate wheel loads as defined as the AIST Technical Report #6, “Allowable Wheel Loads Guide for Heat Treated (321 BHN Minimum) Crane Wheels”

- Applications with high flange pressure and impact loads due to bad rail joints

- Applications with consistently high flange pressure due to severe end truck or rail misalignment – these flanges will bend rather than break

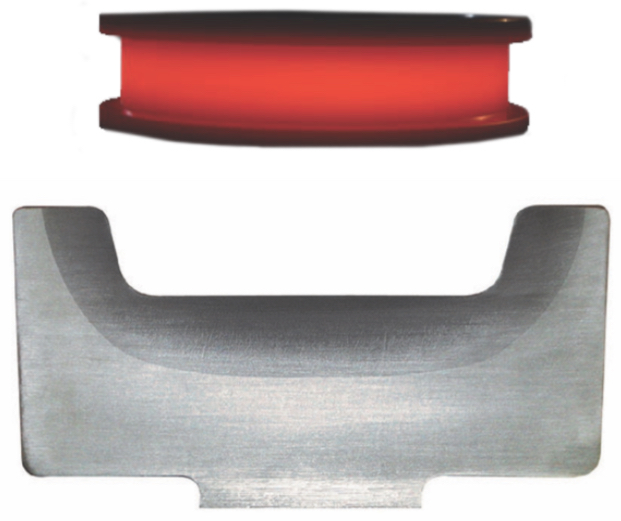

Selectively Hardened AISI-1070 Steel

The “Selective Hardening” heat treating process produces Crane Wheels, Industrial Car Wheels, and Sheaves with a tread and inner flange surface hardness up to 60 Rockwell C-scale (Rc)

- The process involves the full normalizing of the forging followed by a selective heating of the tread and inside flange area and then aggressive quenching in a polymer solution

- The depth of hardness produced in this process exceeds that which is produced by the traditional carburizing process and exceeds the depth of hardness requirements of the AIST Technical Report #6, “Allowable Wheel Loads Guide for Case Hardened (56-60 Rc) Crane Wheels”

- By only hardening the tread and inside of the flanges, the flange core and outside of the flanges remain ductile and resistant to breakage

- This process yields the best combination of maximum load bearing capability and flange toughness in the industry

Recommended Usages

- Cranes with extremely high wheel loads as defined in the AIST Technical Report #6, “Allowable Wheel Loads Guide for Case Hardened (56-60 Rc) Crane Wheels”

- Cranes that operate in areas with high levels of abrasive dust or dirt or other abrasive environments

- Applications with poor end truck and rail alignment that may cause crane skewing resulting in significant flange pressure and where flange breakage is otherwise a concern

- Older cranes that have lost the ability to track correctly during normal operation which results in significant contact between the wheel flanges and rail head

Super Tough AISI-4140 Steel

- The AISI-4140 Super Tough Crane Wheel is capable of supporting extremely high wheel loads with a 500-600 BHN tread hardness while still maintaining superior flange toughness and ductility

- The process involves the full normalizing of the forging followed by a selective heating of the tread and inside flange area and then aggressive quenching in a polymer solution

- The AISI-4140 Alloy Steel allows for significantly greater toughness and impact resistance than a similar hardness carbon steel wheel

- Laboratory testing shows that flanges on AISI4140 “Super Tough” wheels have 50% greater flange strength and 50% greater impact strength than carbon steel wheel flanges

- The increased hardenability of the Alloy Steel allows for deeper hardness penetration and increased spalling resistance

- The depth of hardness achieved with the “Super Tough” wheel is 50% greater than with carbon steel wheels (greater than 40 Rc at .350 inch)

- Available in a variety of hardness ranges up 600 BHN to meet your most demanding applications

Recommended Usages

- Cranes with extremely high wheel loads as defined in the AIST Technical Report #6, “Allowable Wheel Loads Guide for Case Hardened (56-60 Rc) Crane Wheels”

- Older cranes with poorly aligned runways

- Applications with heavy loads and high flange wear

- Applications that have experienced flange breakage