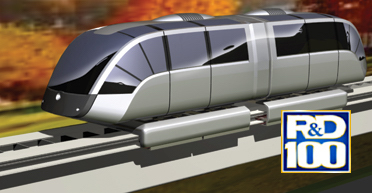

Urban Maglev – Test Vehicle Design & Build

Maglev is a revolutionary approach to public transportation in which vehicles are supported, propelled, and guided by magnetic forces. By minimizing moving parts and physical contact, the Urban Maglev Group (led by General Atomics) transportation solution is low noise and offers lower operating and maintenance costs compared to rail. The low noise, along with the ability to operate in challenging terrain with steep grades (10%) and tight turns (18.3m, 60’), allows alignment design flexibility in dense urban environments. The design achieves the required simplicity with an entirely passive permanent magnet approach. Levitation occurs via generation of eddy currents in the guideway based conductor, whose associated magnetic field then repels the vehicle based permanent magnets. Propulsion force is generated via active guideway based linear synchronous motor coils interacting with the vehicle based sinusoidal permanent magnetic field. Guidance is provided via magnetic attraction to steel guidance rails.

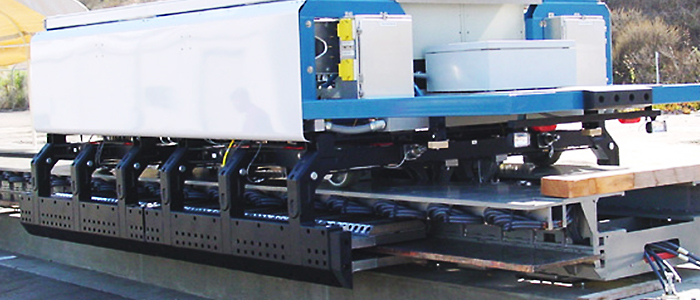

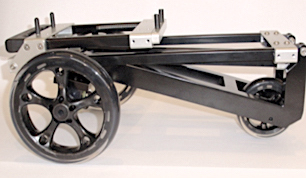

As part of the Urban Maglev Group, Hall Industries was responsible for vehicle and chassis design. We built two complete vehicle chassis, which combined is one vehicle. The design required us to produce large machined aluminum castings, rubber bonded components, aluminum weldments, steel frame weldments, many machined items from steel, stainless steel, bronze and aluminum. We also designed and assembled the vehicle electrical systems, while working closely with other team members to maintain tight systems integration. This project is complete, with the system design approved by the Federal Transit Administration as ready for deployment. The testing program demonstrated systems integration, levitation, propulsion, guidance, ride quality, and vehicle communication and control.