- 1958

Harold G. Hall became general manager of Standard Coil and Manufacturing company that was located on 201 East Carson St in Pittsburgh.

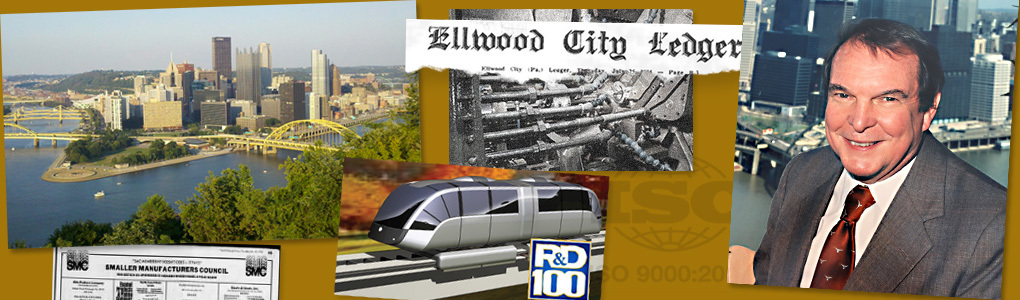

Hall’s History & Timeline

Hall Industries was founded in 1966 in Pittsburgh, PA by WWII Vet and engineer Harold G. Hall (1922-2019) as a contract screw machine shop servicing customers in the steel industry. From the beginning the combination of manufacturing capabilities and engineering talent proved a winning combination for adding value and gaining customer loyalty. We have grown from our humble beginnings with five screw machines located on the south side of Pittsburgh and a focused customer base to become a premier supplier of machined components, fabrications and assemblies.

- 1966

HGH purchased Standard Coil and Manufacturing to start his own company. HALL Industries was founded as a contract screw machine shop servicing customers in the steel industry. From the beginning the combination of manufacturing capabilities and engineering talent proved a winning combination for adding value and gaining customer loyalty. HALL has grown and expanded from our humble beginnings with 5 screw machines and a focused customer base located on the south side of Pittsburgh to become a premier supplier of machined components, fabrications and assemblies.

- 1973

HALL Industries purchased Standard Tool & Machine, located in Blawnox, PA in the Pittsburgh area.

- 1978

HALL Industries purchased Raymond Brass Co in Pittsburgh. HALL also purchased Metaline Co in Bridgeville, PA, and moved the business and equipment to Ellwood City, PA.

- 1981

HALL Industries purchased Barrett Machine Co. located in Pittsburgh’s North Side.

- 1990

HALL purchased the former Barrett Machine Co. in Greenville, SC, adding additional CNC machining capabilities as well as a broader geographical reach. HGH decided to keep all of the four major businesses that he had purchased separate so that he could have he children be in charge of each one. He did not want to encourage them fighting within just one business; the boys would later decide to combine them all and work together as a team.

- 1994

HALL Industries became ISO:9002-1994 Certified.

- 2000

HALL Industries became ISO 9001 Certified.

- 2002

HALL Industries moved into our current facility in Ellwood City, PA. Moving from a limited, 3 story manufacturing site on the south side of Pittsburgh into a 100,000+ sq. ft. single story facility dramatically improved our productivity, lowered our costs and increased our outputs. We have since added many new machines and capabilities, further lowering our costs and increasing our value proposition.

- 2004

R&D 100 Award in partnership with General Atomics & Lawrence Livermore National Laboratory for Iductrack Magnetic Levitation System for Urban Maglev

- 2006

Cutler-Hammer Cost Saving Award

- 2007

HALL Equipment Division became AISC certified and was also listed in PENNDot Bulletin 15, bringing us in to the bridge products business.

- 2007

International Bridge Award for Commerce – Pittsburgh Council for International Visitors

- 2009

HALL Technical Services, LLC was formed to provide GSE and facilities maintenance services to airports and airlines. Hall Tech currently operates facilities servicing Pittsburgh, PA (PIT), New York, NY (JFK) (LGA) (ISP), Norfolk, VA (ORF), Birmingham, AL (BHM), Philadelphia, PA (PHL), Ft. Lauderdale, FL (FLL), Ft. Myers, FL (RSW) and Palm Beach, FL (PBI). In addition, HALL Tech is a value added supplier of repair parts for GSE vehicles.

- 2009

Southwest Airlines Vendor of the Year

- 2010

ILC Dover – Outstanding Supplier Award

- 2014

Hall is awarded “Community Service Award” from the Vietnam Veterans of America

- 2016

HALL Industries opened a trading company in Prague, CZ.

- 2016

Hall Industries plays vital role in machining repair plates for the Liberty Bridge fire. (see linked article for more information)

- 2016

Hall is awarded “2016 Manufacturer of the Year — Large Category” by the Pittsburgh Business Times

- 2019

HALL now consists of six operations all co-owned by the siblings of Harold G. Hall, and John Schlafhauser, Sr.

The business continues to be family run and operated.

- 2019

Hall Industries became ISO 9001:2015 Certified

- 2022

Hall Industries becomes ISO 13485:2016 Certified for Medical Devices